ISOCUT

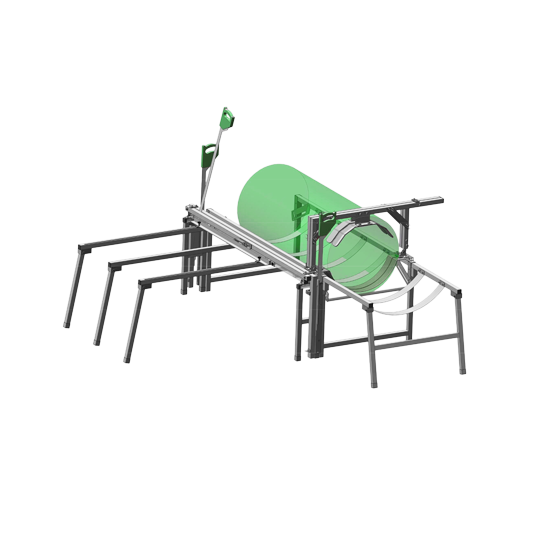

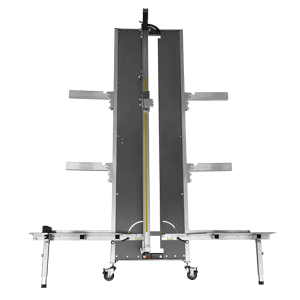

The insulating material cutting system of the extra class for cutting insulation rolls and slabs.

ISOCUT

The insulating material cutting system of the extra class for cutting insulation rolls and slabs.

- Also suitable for heavily compressed wood fiber insulation panels, castors or even aerated concrete.

- Designed according to the principle of a modular system, therefore easily expandable and flexible.

- The cut is made using a commercially available electric saw attached to an adapter.

- Also suitable for heavily compressed wood fiber insulation panels, castors or even aerated concrete.

- Designed according to the principle of a modular system, therefore easily expandable and flexible.

- The cut is made using a commercially available electric saw attached to an adapter.

PRODUCT VERSIONS

Isocut Standard

Isocut Standard  ISOCUT Premium

ISOCUT Premium  Accessories for ISOCUT

Accessories for ISOCUT CUTS INSULATIONAL MATERIAL LIKE:

- Three-layer slabs, composite insulation slabs

- Basement ceiling slabs, foam glass slabs

- Cork, aerated concrete (gas-aerated concrete),

- plastics, gypsum

- Non-plasticized foam and foam glass slabs

- Mineral wool – glass wool slabs,

- also with high specifi c density

- Mineral wool – rock wool slabs,

- also with high specifi c density

- Mineral wool – wood fi bre insulation slabs

- Polystyrene and polyurethane slabs

- Aluminium-laminated insulation materials

- Cellulose

- Hemp

- PU foam

PRODUCT VERSIONS

ISOCUT Basic

ISOCUT Basic  Isocut Standard

Isocut Standard  ISOCUT Premium

ISOCUT Premium  Accessories for ISOCUT

Accessories for ISOCUT CUTS INSULATIONAL MATERIAL LIKE:

- Three-layer slabs, composite insulation slabs

- Basement ceiling slabs, foam glass slabs

- Cork, aerated concrete (gas-aerated concrete),

- plastics, gypsum

- Non-plasticized foam and foam glass slabs

- Mineral wool - glass wool slabs,

- also with high specifi c density

- Mineral wool - rock wool slabs,

- also with high specifi c density

- Mineral wool – wood fi bre insulation slabs

- Polystyrene and polyurethane slabs

- Aluminium-laminated insulation materials

- Cellulose

- Hemp

- PU foam

EQUIPMENT

Electric saws for insulation materials All commercially available electric saws can be used with the ISOCUT.

Electric saws for insulation materials All commercially available electric saws can be used with the ISOCUT.

Height-adjustable stand system

Height-adjustable stand system Safe saw guidance

Safe saw guidance Scales, angles

Scales, angles Miter cuts

Miter cutsAREAS OF APPLICATION

- wall insulation

- flat- and pitched roof insulation

- in between rafter insulation

ADVANTAGES

- The insulation material used is fixed along the entire length of the cut during cutting. It fits tightly without slipping.

- The insulation saw is hooked in with an adapter and guided with double security. This guide ensures a precise, even, clean, right-angled cut with little dust and no effort.

- Whether rolls or panels: With the modular design of the insulation cutter, you can react flexibly at any time to the respective conditions on the construction site and to the insulation material used.

EQUIPMENT

Electric saws for insulation materials All commercially available electric saws can be used with the ISOCUT.

Electric saws for insulation materials All commercially available electric saws can be used with the ISOCUT.

Height-adjustable stand system

Height-adjustable stand system Safe saw guidance

Safe saw guidance Scales, angles

Scales, angles Miter cuts

Miter cutsAREAS OF APPLICATION

- wall insulation

- flat- and pitched roof insulation

- in between rafter insulation

ADVANTAGES

- The insulation material used is fixed along the entire length of the cut during cutting. It fits tightly without slipping.

- The insulation saw is hooked in with an adapter and guided with double security. This guide ensures a precise, even, clean, right-angled cut with little dust and no effort.

- Whether rolls or panels: With the modular design of the insulation cutter, you can react flexibly at any time to the respective conditions on the construction site and to the insulation material used.

TECHNICAL DATA

| cut length | 1.400 mm |

| cut depth | 300 mm |

| angle adjustment | 45 to 90°, both sides |

| weight | 30,0 kg |

TECHNICAL DATA

| cut length | 1.400 mm |

| cut depth | 300 mm |

| angle adjustment | 45 to 90°, both sides |

| weight | 30,0 kg |

ACCESSORIES AND SYSTEM PRODUCTS

Saw variation

Industrial vacuum cleaners

Super ISOTRIM

EQUIPMENT

Saw variation Insulation saws, insulation knife, Bosch electric saw.

Industrial vacuum cleaners For a low-dust work.

Super ISOTRIM ...cuts packaged and unpacked insulation materials (rolls and sheets) quickly and efficiently. more about