Our accessories range

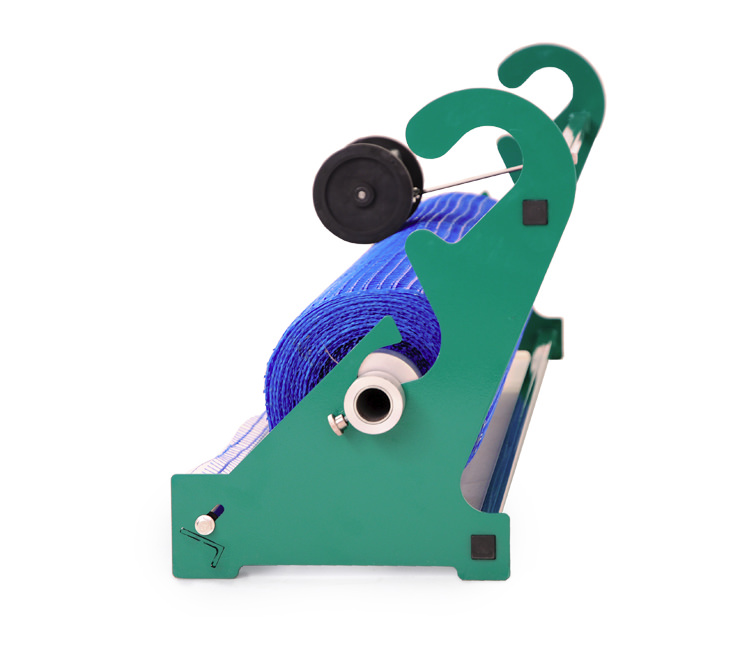

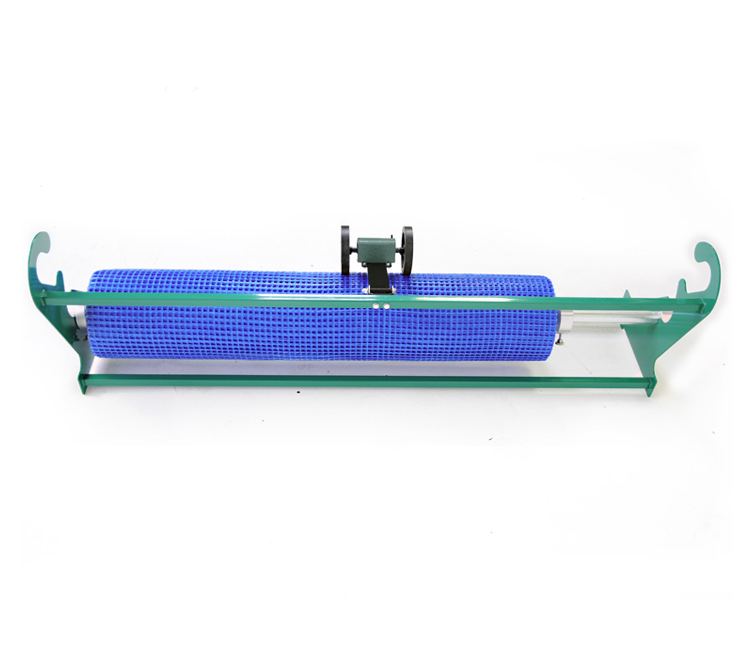

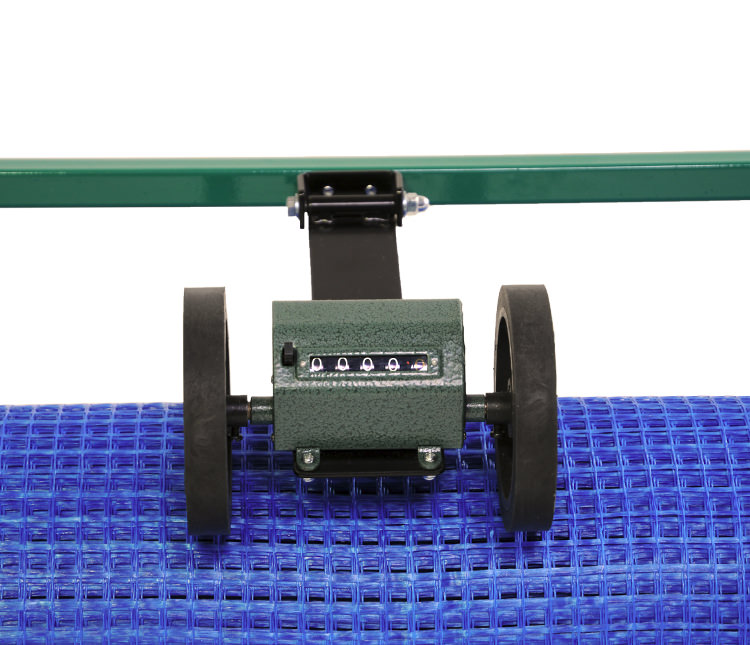

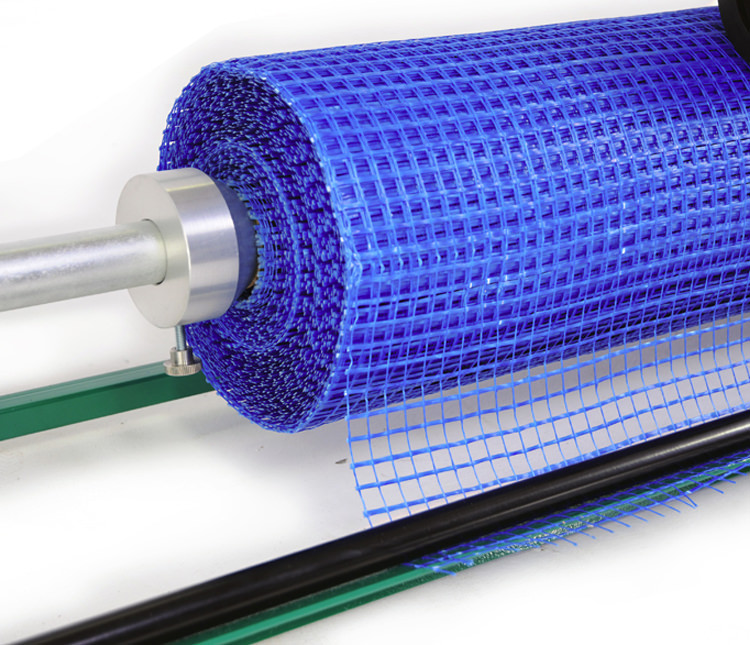

WOVEN FABRIC ROLLER

Cutting out reinforcement fabrics

The woven fabric roller facilitates the cutting out of glass-fiber fabrics in the facade area, vapor-blocking films in the interior area, plastic for the covering of windows etc. Usable both as table-mounted roll dispenser and as scaffold suspension. The metering counter allows a better control-check of the lengths used. Fast roll replacement, thanks to the specially-developed roll mounting.

ROTATING TABLE

Rotating table for facade insulation – efficiently gluing panels to the framework.

Do you know the situation: You stand on the scaffolding and want to prepare a large polystyrene board for gluing.

With one hand you hold the plate, with the other you spread the glue. And with the third hand turn the polystyrene plate to reach the opposite side. Oh well – you have no third hand. But we have the solution for you: our rotating table.

Simply place the polystyrene plate on the rotating table. This fixes itself by the four small spikes at the end of the rotating table arms themselves. Then simply apply the glue to the desired places while slowly turning the rotating table with the polystyrene plate with the other hand. The working position is always in front of you, without you having to stretch or twist. After completion of the order, remove the plate from the rotating table and attach it to the wall.

AREA OF APPLICATION

- wall insulation

ADVANTAGES

- Particularly sturdy because of stainless steel

- Quick fixation of the plate through the mandrels at the end of the turntable arms

- Suitable for all common types of scaffolding

WOVEN FABRIC ROLLER

Cutting out reinforcement fabrics

The woven fabric roller facilitates the cutting out of glass-fiber fabrics in the facade area, vapor-blocking films in the interior area, plastic for the covering of windows etc. Usable both as table-mounted roll dispenser and as scaffold suspension. The metering counter allows a better control-check of the lengths used. Fast roll replacement, thanks to the specially-developed roll mounting.

ROTATING TABLE

Rotating table for facade insulation – efficiently gluing panels to the framework.

Do you know the situation: You stand on the scaffolding and want to prepare a large polystyrene board for gluing.

With one hand you hold the plate, with the other you spread the glue. And with the third hand turn the polystyrene plate to reach the opposite side. Oh well – you have no third hand. But we have the solution for you: our rotating table.

This is easily hooked to the desired working position on the upper railing rail and fixed if necessary on the lower railing rail. And off you go.

Simply place the polystyrene plate on the rotating table. This fixes itself by the four small spikes at the end of the rotating table arms themselves. Then simply apply the glue to the desired places while slowly turning the rotating table with the polystyrene plate with the other hand. The working position is always in front of you, without you having to stretch or twist. After completion of the order, remove the plate from the rotating table and attach it to the wall.

AREA OF APPLICATION

- wall insulation

ADVANTAGES

- Particularly sturdy because of stainless steel

- Quick fixation of the plate through the mandrels at the end of the turntable arms

- Suitable for all common types of scaffolding

BUCKET SUPPORT

The bucket support for insulation work on the scaffolding

The bucket support is an excellent helper in the hard physical work that the construction professions bring with it.

- With a weight of only 4 kg, the bucket carrier can be loaded up to 28 kg. Suitable for all standard paint and cleaning buckets.

- Work on the scaffolding: By attaching to the railing stringer, the bucket is always at working height .

- Equipped with casters : The bucket support is suspended in the scaffold railing stringer, and thanks to the attached sliding rollers on the railing stringer, it can be easily pushed further.

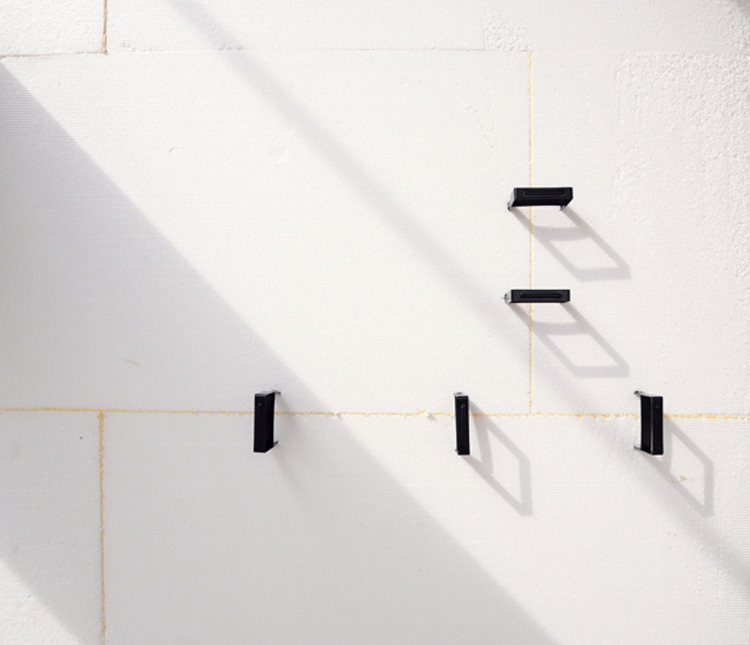

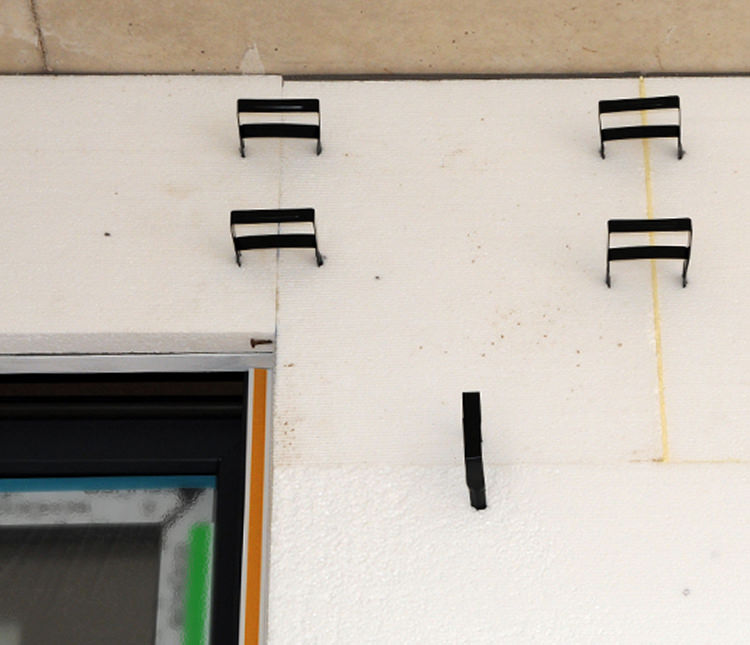

STYROGRIPS

Practical helpers in the installation of polystyrene or other rigid foam panels in construction.

Our Styrofoam clamps: The Styrogrips enable a distance-free bonding of your insulation elements. As a result, you get a defect-free thermal image.

- When attaching polystyrene or other hard foam boards, it is particularly important that these are glued together seamlessly to avoid thermal bridges. But the freshly applied to the foam board adhesive is not so adhesive immediately after application, he can fix the plate on its own on the ground. Also over door and window lintels as well as reveals come the Styrogrips increasingly used. They allow a distance-free bonding of your insulation elements. As a result, you get a defect-free thermal image.

- After attaching the Styrofoam plate it is fixed with the Styroporklemmen on the adjacent plate. For this, the clamp is simply pressed into the material of both plates.

- By the beaded execution of the brackets they have the necessary rigidity to hold the two plates firmly together. After the adhesive has cured, the clamps are simply pulled out of the rigid foam panels.

- The brackets can be used both outdoors and indoors.

- The styrofoam brackets are made of powder-coated steel. Any adhesive that sticks can easily be wiped off.

- Packing unit: 10 styrofoam pegs “Styrogrip”

BUCKET SUPPORT

The bucket support for insulation work on the scaffolding

The bucket support is an excellent helper in the hard physical work that the construction professions bring with it.

- With a weight of only 4 kg, the bucket carrier can be loaded up to 28 kg. Suitable for all standard paint and cleaning buckets.

- Work on the scaffolding: By attaching to the railing stringer, the bucket is always at working height .

- Equipped with casters : The bucket support is suspended in the scaffold railing stringer, and thanks to the attached sliding rollers on the railing stringer, it can be easily pushed further.

STYROGRIPS

Practical helpers in the installation of polystyrene or other rigid foam panels in construction.

Our Styrofoam clamps: The Styrogrips enable a distance-free bonding of your insulation elements. As a result, you get a defect-free thermal image.

- When attaching polystyrene or other hard foam boards, it is particularly important that these are glued together seamlessly to avoid thermal bridges. But the freshly applied to the foam board adhesive is not so adhesive immediately after application, he can fix the plate on its own on the ground. Also over door and window lintels as well as reveals come the Styrogrips increasingly used. They allow a distance-free bonding of your insulation elements. As a result, you get a defect-free thermal image.

- After attaching the Styrofoam plate it is fixed with the Styroporklemmen on the adjacent plate. For this, the clamp is simply pressed into the material of both plates.

- By the beaded execution of the brackets they have the necessary rigidity to hold the two plates firmly together. After the adhesive has cured, the clamps are simply pulled out of the rigid foam panels.

- The brackets can be used both outdoors and indoors.

- The styrofoam brackets are made of powder-coated steel. Any adhesive that sticks can easily be wiped off.

- Packing unit: 10 styrofoam pegs “Styrogrip”

CUTTING WIRE FOR HARD FOAM CUTTERS

Cutting wires for hot wire hard foam and poystyrene cutters

Only with the special Styrofoam cutting wire you can achieve accurate results and at the same time benefit from a comfortable and clean cutting technique.

With the hot wire for a clean cut

If you attach great importance to clean edges when cutting polystyrene and do not like electrostatically charged waste, you will use a professional cutting wire for polystyrene cutters for this work. Because only with the Styrofoam cutting wire you can achieve accurate results and at the same time benefit from a comfortable and clean cutting technique. Cutting wire for Styrofoam cutter is suitable for commercial and private use in a wide variety of applications.

How hot wires work

The Styrofoam cutting wire is a so-called heating conductor wire. Made of a nickel-based alloy, preferably nickel-chromium-copper alloy, the wire for Styrofoam cutter has special properties. These are in particular a good corrosion resistance and, for cutting wire for Styrofoam cutter indispensable, the high temperature resistance. This is necessary because the cutting wire must heat up sufficiently high. Because the melting point of polystyrene lies in the temperature range of approximately 180 ° C. Only when the wire for Styrofoam cutter reaches this high temperature, a clean and, above all, smooth cutting edge results.

Areas of application of Styrofoam cutting wire

The cutting wire for Styrofoam cutter is always used, if you require an exact cut and high accuracy of fit. This applies, for example, for the exact cutting of the thermal insulation. Use a knife for this work, fringe the interfaces and air circulates between the adjacent insulation boards. With heat, you melt the cut edges and get a smooth and perfectly fitting surface. If you need wedge-shaped, round or semicircular cutouts, realize them only by the application of heat. Only in this case you will receive the desired fit and dimensionally accurate result.

SCAFFOLD BRACKET

Special scaffold bracket for polystyrene cutting machines – efficient cutting of rigid foam boards in construction.

Cutting polystyrene slabs directly on the scaffolding is possible with the special scaffold bracket for the polystyrene cutters. The scaffold bracket is compatible with all common polystyrene cutters.

- The bracket can be turned 90 degrees.

- The scaffolding bracket is fastened to the back of the Styrofoam cutter with 4 screws and can be attached to the scaffolding with quick clamps.

CUTTING WIRES FOR HARD FOAM CUTTERS

Cutting wires for hot wire hard foam and poystyrene cutters

Only with the special Styrofoam cutting wire you can achieve accurate results and at the same time benefit from a comfortable and clean cutting technique.

With the hot wire for a clean cut

If you attach great importance to clean edges when cutting polystyrene and do not like electrostatically charged waste, you will use a professional cutting wire for polystyrene cutters for this work. Because only with the Styrofoam cutting wire you can achieve accurate results and at the same time benefit from a comfortable and clean cutting technique. Cutting wire for Styrofoam cutter is suitable for commercial and private use in a wide variety of applications.

How hot wires work

The Styrofoam cutting wire is a so-called heating conductor wire. Made of a nickel-based alloy, preferably nickel-chromium-copper alloy, the wire for Styrofoam cutter has special properties. These are in particular a good corrosion resistance and, for cutting wire for Styrofoam cutter indispensable, the high temperature resistance. This is necessary because the cutting wire must heat up sufficiently high. Because the melting point of polystyrene lies in the temperature range of approximately 180 ° C. Only when the wire for Styrofoam cutter reaches this high temperature, a clean and, above all, smooth cutting edge results.

Areas of application of Styrofoam cutting wire

The cutting wire for Styrofoam cutter is always used, if you require an exact cut and high accuracy of fit. This applies, for example, for the exact cutting of the thermal insulation. Use a knife for this work, fringe the interfaces and air circulates between the adjacent insulation boards. With heat, you melt the cut edges and get a smooth and perfectly fitting surface. If you need wedge-shaped, round or semicircular cutouts, realize them only by the application of heat. Only in this case you will receive the desired fit and dimensionally accurate result.

SCAFFOLD BRACKET

Special scaffold bracket for polystyrene cutting machines – efficient cutting of rigid foam boards in construction.

Cutting polystyrene slabs directly on the scaffolding is possible with the special scaffold bracket for the polystyrene cutters. The scaffold bracket is compatible with all common polystyrene cutters.

- The bracket can be turned 90 degrees.

- The scaffolding bracket is fastened to the back of the Styrofoam cutter with 4 screws and can be attached to the scaffolding with quick clamps.

PEDAL SWITCH FOR HARD FOAM CUTTERS

Pedal switch for hard foam or insulation material cutters

- metal design

- with protective hood against unintentional switching on

- with XLR plug

CARRYING CASE FOR INSULATION CUTTERS

Special & stable carrying cases for styrofoam & insulation material cutters

With the sturdy transport cases especially for our styrofoam or insulation cutters, the devices are optimally protected on the construction site and on the way there from damage.

- from screen-print wood

- made of plastic

PEDAL SWITCH FOR HARD FOAM CUTTERS

Pedal switch for hard foam or insulation material cutters

- metal design

- with protective hood against unintentional switching on

- with XLR plug

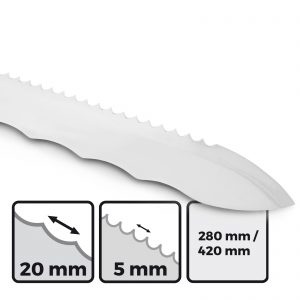

DOUBLE-SIDED INSULATION KNIFE

Double-sided insulation knife with with a sharp blade, specially for cutting natural insulating materials like glas wool, rock woll and wood wool.

Characteristic of the blade

One Knife, two cuts:

One blade with a sawcut, the second one with a serrated edge – for more flexibility when cutting.

Knife tip:

Profiled tip for easy penetration into soft insulating materials.

Material:

Stainless steel with mirror polish – perfectly smooth surface.

Available in two lengths

Model 1: Blade length: 280 mm / Total length: 416 mm

Model 2: Blade length: 420 mm / Total length: 456 mm

|

Material, blade

|

stainless steel

|

|

Blade type

|

sawcut and serrated edge

|

|

Blade Finish

|

polished

|

|

Blade thickness

|

1,2 mm

|

|

Blade height

|

27 mm

|

|

Protective cover

|

nylon sheath with suspension

|

|

Material, handle

|

plastic with soft rubber insert

|

|

Finger protection

|

available

|

|

Length, Model 1:

|

Blade length: 280 mm / Handle length: 136 mm / Total length: 416 mm

|

|

Length, Model 2:

|

Blade length: 420 mm / Handle length: 136 mm / Total length: 456 mm

|

DOUBLE-SIDED INSULATION KNIFE

Double-sided insulation knife with with a sharp blade, specially for cutting natural insulating materials like glas wool, rock woll and wood wool.

Characteristic of the blade

One Knife, two cuts:

One blade with a sawcut, the second one with a serrated edge – for more flexibility when cutting.

Knife tip:

Profiled tip for easy penetration into soft insulating materials.

Material:

Stainless steel with mirror polish – perfectly smooth surface.

Available in two lengths

Model 1: Blade length: 280 mm / Total length: 416 mm

Model 2: Blade length: 420 mm / Total length: 456 mm

|

Material, blade

|

stainless steel

|

|

Blade type

|

sawcut and serrated edge

|

|

Blade Finish

|

polished

|

|

Blade thickness

|

1,2 mm

|

|

Blade height

|

27 mm

|

|

Protective cover

|

nylon sheath with suspension

|

|

Material, handle

|

plastic with soft rubber insert

|

|

Finger protection

|

available

|

|

Length, Model 1:

|

Blade length: 280 mm / Handle length: 136 mm / Total length: 416 mm

|

|

Length, Model 2:

|

Blade length: 420 mm / Handle length: 136 mm / Total length: 456 mm

|

Every new machine starts with an innovation. Read more about how we have passionately developed and produced our Insulation Cutters & Rigid Foam Cutter and have steadily expanded our range.

Pro Bauteam Vertriebs- und Produktionsgesellschaft mbH

Grafenheider Straße 103

33729 Bielefeld

Germany